KLW has strengthened its engineering and R&D department and is now focusing on developing new products for current customers’ needs. In 2016 our team is focused on 4 main projects.

Cyril Duhamel, Head of R&D and product policy:

“KLW is becoming more experienced and flexible producer than ever. Along with development of the production capacities, we strengthen our engineering and R&D team.

We understand well the new challenges given by railway industry and strive to offer the best solutions to the customers.

This year we are focusing on improving the life cycle cost and usage performances of KLW products. The objective of our works is to enhance mechanical properties of products in order to offer to our customers longer lifespan, lighter products and high safety.”

Innovative Class D

The Heavy Haul market is one of KLW’s priorities. Increasing axle load is a strategic objective to improve the competitiveness of freight wagons.

KLW is involved in the AAR project to develop an innovative steel grade that supersedes current Class D. Developing steel grade with a better resistance to RCF and extreme usage conditions is a significant industrial challenge.

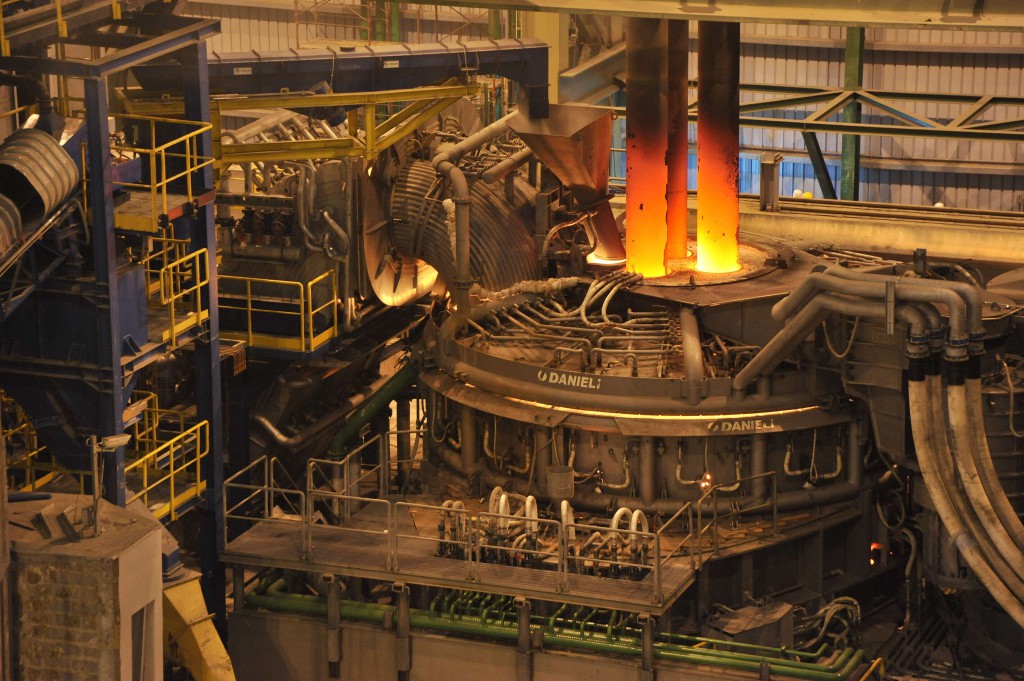

Now we are developing a new chemical composition of steel and heat treatment mode. The first heat is planned to be produced in October.

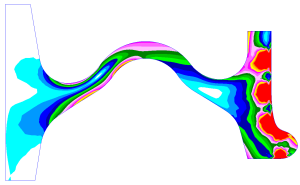

ER7 and ER8 Evolve

Increasing wheels’ lifespan for wagons and passenger coaches is a key objective.

KLW engineers strive to increase mechanical properties of ER7 and ER8 steel grades to improve RCF and thermal resistance. At the same time, wheel material characteristics remain within the limits of European standard EN13262.

Mechanical properties, namely yield strength, ultimate strength, elongation, impact resistance, hardness, fracture toughness, will reach the optimal values.

Numerous heat treatment modes for checking whether current steel grades can achieve the target results were tested. The next step is developing new steel compositions for ER7 and ER8 by adding alloying elements.

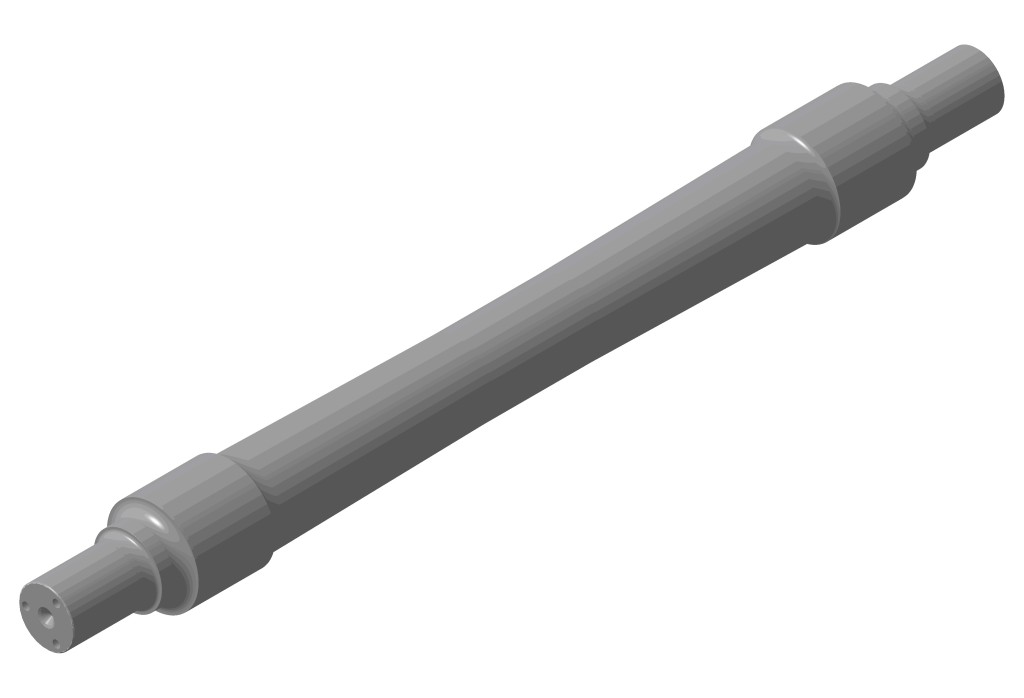

European standard freight axle

The European standard freight axle will progressively replace existing axles. It offers a better safety rate and reduces maintenance costs.

We are developing a new axle design for axle loads of 22.5 t and 25 t and for wheels of 840-920 mm. We included all requirements of UIC group about the axle development. Our team is also selecting the appropriate protective Class 1 coating. This combination will enable us to improve operating properties of the freight axle and railroad safety and to limit maintenance costs.

The combination of the result of this project and the project aimed at improving steel grades ER7 and ER8 will enable us to offer a new generation of freight wheelsets to our customers. It is a promising area for discovering innovative design solutions.

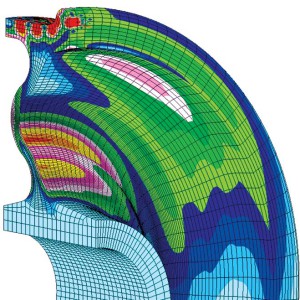

ULTIMATE: The new KLW product line of low stress wheels

KLW is launching its own product line, called ULTIMATE, of low stress wheels for European freight market.

ULTIMATE line has been developed to meet all European requirements for mechanical resistance, thermomechanical resistance during braking on the thread, a low noise level. The design is developed in accordance with EN 13979, UIC 510-5 and with production standards EN 13262, BN 918 277 (Category 2).

The design of 920 mm wheel is now complete. We also initiated the development of 840 mm design. The production of the first trials and its testing is scheduled in October. By the end of the year the new product will be under TSI certification.

The next step is the development of a 1000 mm wheel in this product line.

ULTIMATE wheels will be delivered to customers with definitive painting. Upon customer request, we can also deliver them with finished bore. KLW will provide a 5-year guarantee to such wheels and its covering.