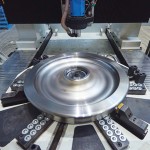

The new facilities of finish operations provide KLW with the ability to carry out the finish machining of the wheels bore and various types of web drillings. The capacity of the 2 CNC machining centers standings at 60,000 wheels per year, depending on their design.

The painting shop includes cleaning, painting and drying chambers and provides capacity up to 60,000 wheels per year.

The high level of geometry control is reached by the most modern coordinate measuring machine, which will be used during FAI and mass production inspection.

There is also new balancing machine for wheel self-balancing and balance correction. Moreover the production line includes the new MPI unit for non-destructive testing.

This new equipment enables us to produce a wide range of products for the passenger market segment, metro and complex locomotive wheels. The new production facilities correspond with the requirements of leading rolling stock constructors and national railway operators, such as Siemens, Bombardier, Hyundai, Alstom, Deutsche Bahn, SBB, OBB, DSB, RENFE.